Configuration

1. WATER & FOAM TANKS

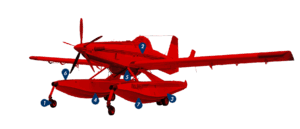

4. The Airframe

A rugged aircraft built with confined area operations and maneuverability in mind. The AT-802F has been purpose built and FAA-certificated for aerial firefighting. It can be refitted with conventional landing gear in the off season to perform additional missions.

Single-Seat & Two-Seat Trainer Models Available

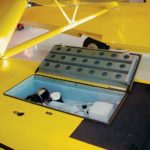

5. FIRE GATE

The fire gate controls the rate and volume of water release. It allows the pilot to perform accurate salvo or string drops.

Fire gate options include:

- Air Tractor Gen II FRDS (Factory Standard)

- Hydramax Fire Gate

- Hatfield Fire Gate

2025 Updates to the Fire Boss

Fire Boss is proud to announce several improvements to design and configuration options that result in 125+ pounds weight savings and a shift in center of gravity.

Wipline 10000 Amphibious Floats

6. Retractable Landing Gear

Rugged amphibious versatility for runway, gravel or water take-offs and landings

7. High Efficiency water Scoops

Simple, easy to maintain, and effective. The scoops are designed to be safely deployed at landing speeds

8. WATER TRANSFER TUBE

Moves the scooped water up the float pylon and into the fuselage holding tank.

9. Removable Foam Tanks

Optional removable tanks slip inside the floats and add up to 60 USG (226 L) foam capacity to the 18 USG (69 L) fuselage foam tanks

Modifications for the Fire Boss

Single Water Rudder

Less maintenance and less aft weight with no change in control.

Step Removal

Remove one side or both, for up to 21 pound reduction in aircraft empty weight.

True Blue Power TB60 Lithium-ion Aircraft Battery

70 pounds reduction in weight! Zero capacity checks, cooler starts, lasts 8 years and 90% less environmental waste than lead acid batteries.

CorrosionX

Exclusively through Wipaire, CorrosionX can be applied to your new Fire Boss floats and Air Tractor.

Specifications

Standard Equipment

- Air Tractor AT-802F or AT-802AF

- PT6A-67AG 1.350 HP or PT6A-67F 1,600 HP engine

- Hartzell 5-Blade c/s reversing 115” or 19” (291.1 cm or 302.2 cm) propeller

- Fuselage foam tank 18 USG/68 L

- Auto / manual foam transfer system

- Wipline® 10000 series amphibious floats

- Normal and emergency landing gear retraction system

- Landing gear advisory system

- Two retractable water scooping probes

- Auto/manual hopper quantity pre-select (Operational Load Monitoring System)

- Higher capacity hopper venting system

- Emergency hopper overflow system

- Float emergency bilge system

- Visual and aural engine over-torque warning system

- Water scooping probe advisory system

- Electronically controlled retractable water rudders

- Single water/retardant ground-loading port

- Stall improvement array kit (vortex generators)

- Finlets & ventral fin

- Flow generators (2-seat aircraft installation)

- Lead free ballast management system (2-seat aircraft installation)

- Hardware for 1,600 SHP Pratt & Whitney PT6A-67F engine installation

- Replaceable access cover seals

- Single piece nose fork

- Scoop lock out for firegate arming

Optional Equipment

- 1,600 SHP PT6A-67F engine upgrade kit

- Rear cockpit trainer kit for AT-802 2-seat

- Float conversion kit for 2-seat aircraft

- Additional 30 gallon /113 liter foam tank

- AT-802A or AT-802 landplane stall improvement array

- CorrosionX

- True Blue Power TB60 Lithium-Ion Battery

Performance

| Gross Takeoff Weight (Land) | 16,000 lbs // 7,257 kg |

| Gross Takeoff Weight (Water) | 11,500 lbs // 5,216 kg |

| Maximum Landing Weight (Land) | 12,300 lbs // 5,579 kg |

| Maximum Scooping Weight | 16,000 lbs // 7,257 kg |

| Maximum Landing Weight (Water) – Full Stop | 11,500 lbs // 5,216 kg |

| Land Take-Off Run | 1,970 ft // 600 m |

| Land Take-Off Over 50 ft Obstacle | 3,299 ft // 1,005 m |

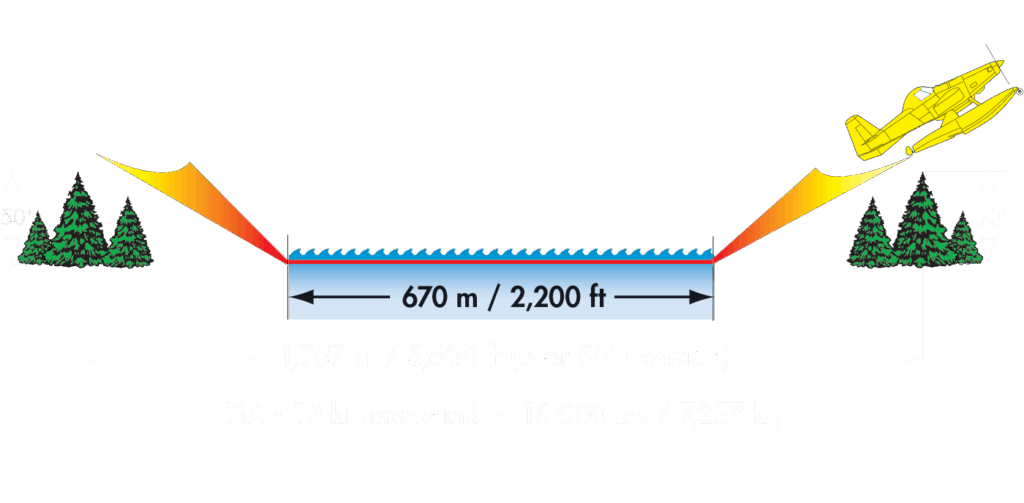

| Water Take-Off or Scooping Run | 2,200 ft // 670 m |

| Water Take-Off or Scooping Run Over 50 ft Obstacle | 5,600 ft // 1,707 m |

| Approximate Empty Weight | 8,775-8,975 lbs // 3,980-4,070 kg |

| Approximate Useful Load | 6,925-7,225 lbs // 3,141-3,277 kg |

| Max Cruise Speed At 16,000 lbs / 7,257 kg | 150 KIAS |

| VS (16,000 lbs / 7,257 kg – 10° Flap) | 75 KCAS |

| VS (16,000 lbs / 7,257 kg – 30° Flap) | 72 KCAS |

| Rate of Climb At 16,000 lbs / 7,257 kg | 892 ft/min // 272 m/min |

Water Delivery Based on Distance From WAter Source

| Distance between fire and water source (in US Miles) | Average turnaround time (in Minutes) | Water delivered to fire per hour (in US Gallons) |

| 1 | 3 | 14,000 |

| 5 | 4 | 10,500 |

| 10 | 6 | 7,000 |

| 15 | 9 | 4,666 |

| 20 | 11 | 3,818 |

Water Take-Off Run

Land Take-Off Run